In 2023, the DVSA updated its guide to maintaining roadworthiness to include the following statement on brake testing:

‘’From April 2025 there will be an expectation that a laden roller brake test or EBPMS will be the only accepted methods to assess brake performance’’

Haulage operators like ourselves are required to comply with a stringent set of road worthiness criteria. Part of this includes monitoring the braking performance of the fleet’s vehicles, conducted through the use of a roller brake tester (RBT). However, new legislation will be coming into effect that will impact on how brake tests are carried out.

From 2025, laden roller brake tests or electronic brake performance monitoring systems (EBPMS) will become the only accepted methods for brake testing. Our Group Compliance Manager, Ross Burrough, explores what this will mean for maintaining safety standards.

Developments in technology continue to play an integral part in maintaining and improving standards across the haulage industry. The introduction of Electronic Brake Performance Monitoring Systems (EBPMS) is one such development.

EBPMS goes beyond the usual method of roller brake tests (RBTs) used in conducting the mandatory brake tests conducted as part of a vehicle’s regular safety inspections. While they have been effective for many years, RBTs do leave some gaps in the understanding of the overall health of a trailer by missing potential issues in between safety inspections. They can also be costly, with up to four tests being required to be carried out each year. For large fleets, the cost of each of these can soon become significant, and that is not even taking into account the downtime that RBTs cause.

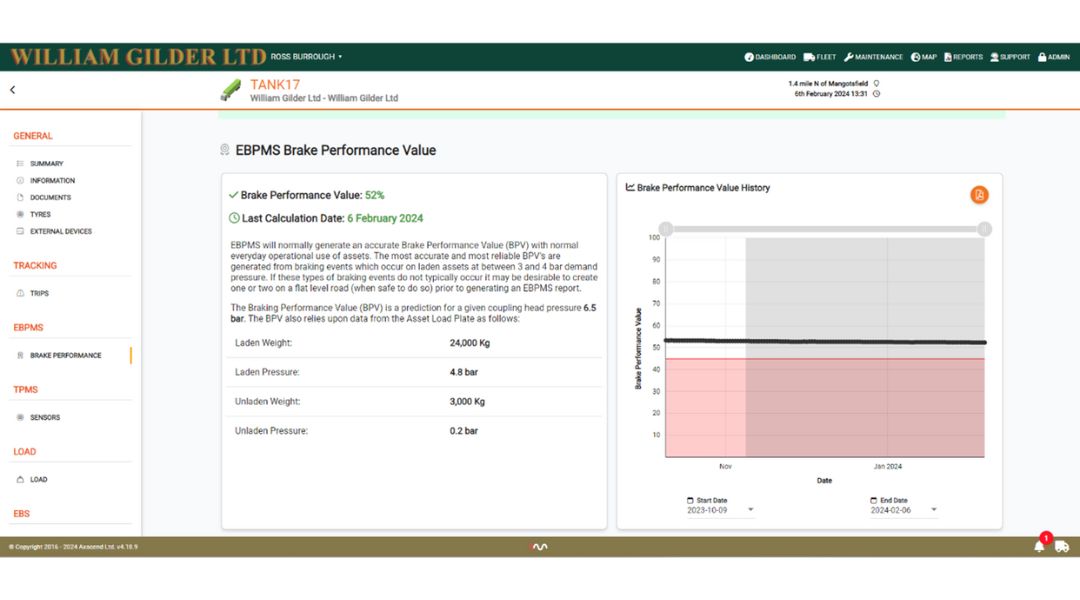

By contrast, EBPMS conducts real-time monitoring through telematics and sensors positioned on each wheel. The data is analysed through a series of algorithms, which ultimately leads to the identification of potential issues before they escalate and allows for preventive steps to be taken at the soonest opportunity. In addition, reports can be compiled in a matter of minutes, again, resulting in swift actions taken in order to maintain optimum vehicle standards.

The added benefit of remote monitoring for fleet operators is that potential faults can be picked up in between the mandatory periodical inspections, which can be as little as six weeks depending on the age and type of vehicle. Knowing that the vehicle or vehicles may need to be worked on ahead of time, with the aid of data produced by EBPMS, ensures that any gaps in operation can be managed and operations can be maintained.

For large operators, this represents a significant change in the way in which vehicle maintenance schedules are compiled, and there is not much time to prepare for it. In order to get into the best possible position ahead of 2025, it is recommended that a laden roller brake test is carried out at every inspection, whether this is a 6-weekly or as part of its annual inspection. Brake performance tests can be conducted up to seven days prior to a safety inspection, but the sooner these can be carried out, the better.

Make no mistake, the changes to brake testing requirements will take some time to bed in. Yet the improvements in road worthiness, and ultimately safety, will have far reaching benefits for the haulage industry and the public who rely on trailers for the majority of the goods they use daily.

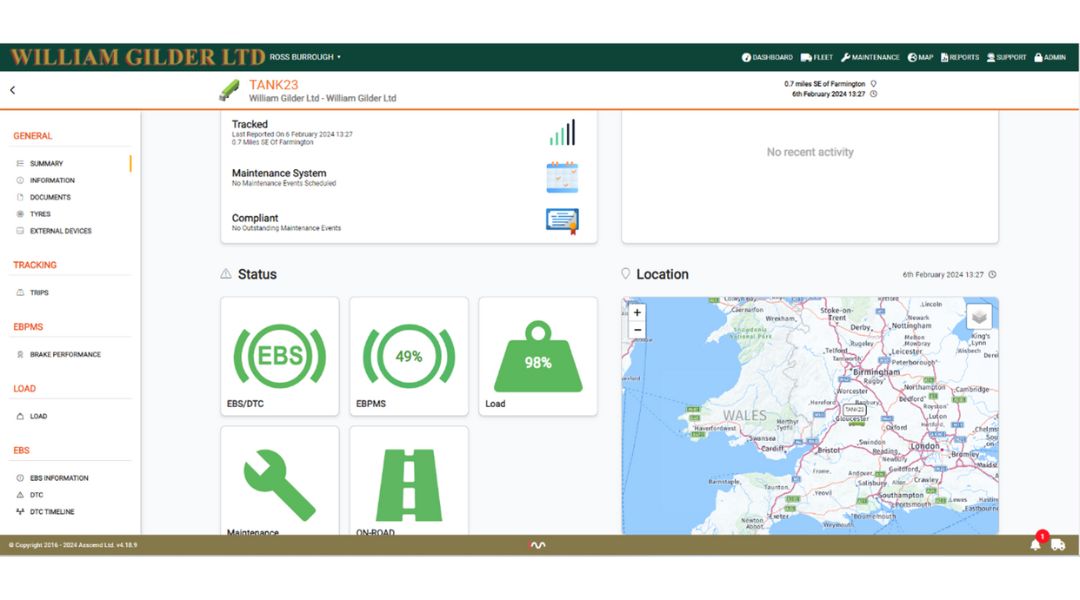

At William Gilder Group, we have partnered with telematics specialists Axscend to carry out EBPMS on our fleet of 70 trailer vehicles. The Trailermaster system has given us superior knowledge and insights into the performance of our fleet, the benefits of which we are seeing in the continuing high standards of our operation.

By removing the requirement to roller brake test our entire trailer fleet we can utilise the existing testing equipment to service our third party client base that do not operate an EBPMS system and who will require laden roller brake testing as part of their regulatory maintenance programs.

Contact our workshop team for more about our inspection support services.