Sustainability

At William Gilder Group, farming lies at the core of our business, and we take every step to minimise our impact on the environment. Since 2009, we have obtained ISO 9001 Quality Management Systems and ISO 14001 Environmental Management Systems accreditations as a mark of our commitment to sustainability. We adhere to PAS110 standards set by the Environment Agency when spreading our digestate.

Nevertheless, we recognise that there is always room for improvement in preserving our natural resources. In 2015, our senior management team formulated a formal Environmental Policy Statement to establish focus and key objectives in line with our ISO 14001 certified management system.

Our company is dedicated to achieving a sustainable balance between present and future business needs, as well as those of society and the natural environment. To demonstrate our commitment to environmentally responsible operations, we have developed a Corporate Social Responsibility (CSR) initiative.

Our primary environmental goal is to minimise the consumption of energy, water, and natural resources. This approach aligns with the concept of ‘One Planet Living’ (Bioregional/WWF, 2002).

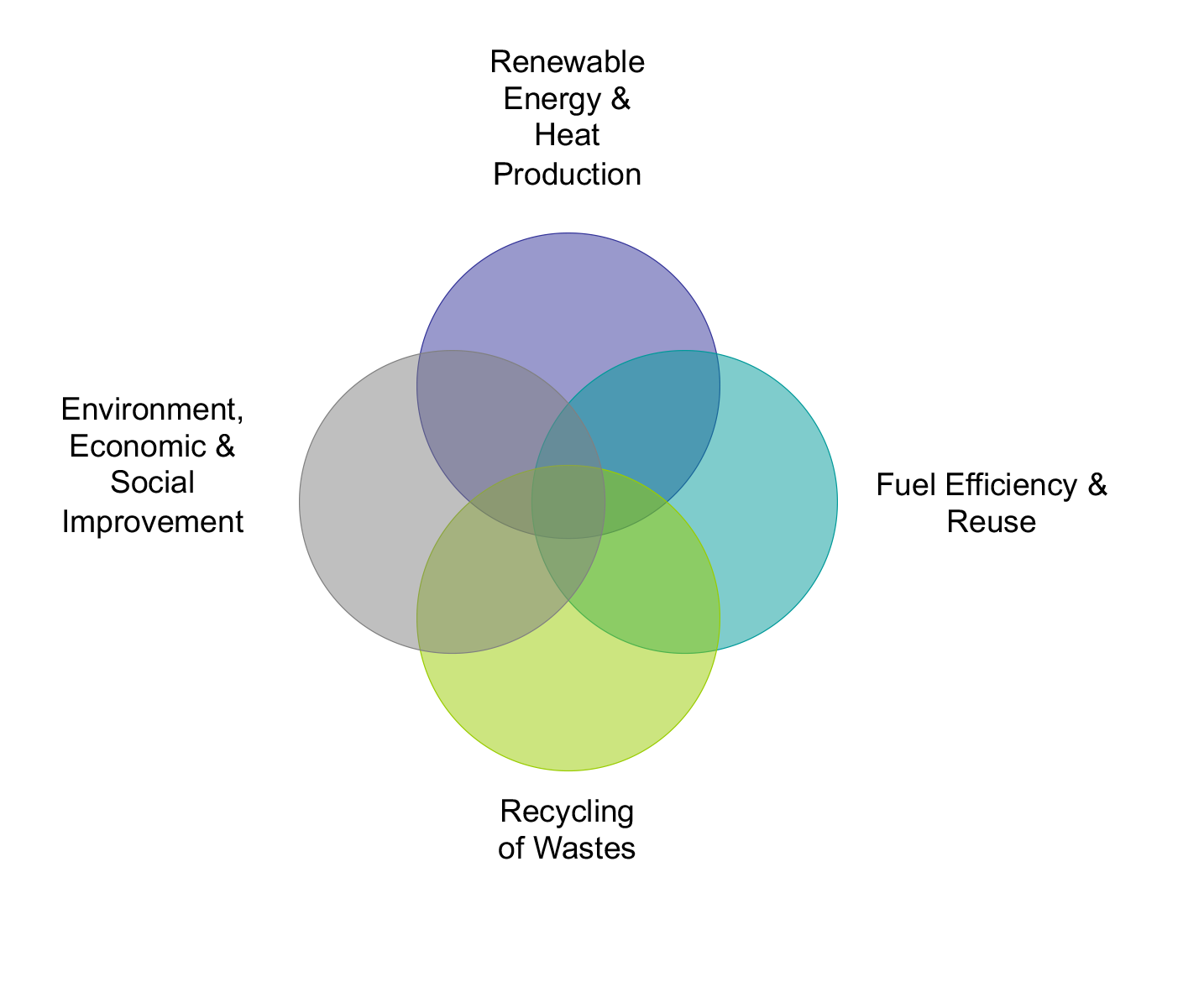

To achieve this objective, we have identified various company projects and operational themes that address specific concepts:

- Renewable Energy and Heat Production

- Environment, Economic, and Social Improvement

- Fuel Efficiency and Reuse

- Recycling of Wastes

Since 2016, we have implemented projects across our three operational premises in Teddington Hands, Toddington, and Gretton Fields (all in Gloucestershire), as well as our commercial transport-led operations throughout England and Wales.

Noteworthy projects and operations that the company has undertaken include:

Renewable Energy and Heat Production: We have installed two Waste Incineration Directive (WID) certified biomass boilers at our Toddington premises. These boilers use 6,000 tonnes of C-grade waste wood chip annually, which would otherwise end up in landfills. The boilers produce process heat (1MW per boiler unit) and generate on-site power through an Organic Rankine Cyclone (ORC) unit, producing up to 40kw of electricity per hour.

Additionally, we have installed solar panels on the roofs of our Teddington and Toddington premises. This initiative generates over 200,000 kwh of electricity per year and leads to cost savings of up to £60,000 across the two sites. Further enhancement of our green power production will be completed in 2020 with the extension to the Teddington Offices and Workshop.

Fuel Efficiency and Reuse: Our fleet consists of 50 Euro 6 rated articulated lorries and 15 rigid bulk tipping vehicles. We maintain a rolling stock agreement with Scania UK to ensure our fleet remains up to date, thereby minimising our environmental impact and CO2 emissions.

Through collaboration with Scania UK and our transport planning software (Verilocation), we optimise the routes for our vehicles, prioritising efficiency and environmental friendliness. We closely monitor driving habits with increased data availability and offer training to drivers to maximise vehicle utilisation. This enables us to measure fuel consumption and CO2 emissions for our fleet (978 tonnes produced pre-offsetting in 2019), setting annual improvement targets and exploring options for offsetting CO2 emissions.

To save on electricity and heating fuels, we utilise waste oil heaters in our Teddington and Gretton-based workshops. Furthermore, we exclusively use waste-derived wood chip fuel for our boilers, reducing the consumption of virgin wood fuels by approximately 6,000 tonnes annually.